The SOX is causes acid rain and greenhouse effect and damage the ozone layer is one of the main material, the SOX emissions from coal-fired power plants is the main source of air pollution. Flue gas desulfurization can be roughly divided into two kinds of dry method and wet method, load type transition metal oxide dry flue gas desulfurization because than traditional wet flue gas desulfurization has more advantages and is paid great attention to by people.

The principle of renewable aluminum copper oxide dry flue gas desulfurization is:

After the flue gas flow through the reactor (located in the low temperature economizer) within the particles of alumina carrier, the flue gas SOXReact with load on the alumina oxide generated CuO4 (300 ℃ -- 500 ℃) so as to achieve the aim of removing SOX in flue gas, the main reactions are as follows

CuO + SO2 + 1/2 O2 → CuO4

CuO + SO3 → CuO4

Desulfurizer after sulfur saturation absorption, access to a reducing gas such as hydrogen, methane, etc.) for regeneration, CuSO4 preliminary reduction into elemental copper. After preliminary regeneration of elemental copper can quickly CuO oxidation by oxygen in the air

Making desulfurizer regeneration, completely recycled. The release of the desulfurizer was born SO2 after concentrated sulfuric acid can be made or elemental sulfur. The whole process of regeneration in the curing reaction of the same temperature range, the system without having to heat. The main reactions are as follows:

CuSO4 + 2 H2 → CuO + SO2 + 2 H2O

CuO +1/2 CH4 → Cu + SO2 + 1/2 CO2 + H2O

Cu + 1/2 O2 → CuO

Compared with the conventional methods of flue gas desulfurization, aluminum oxide dry flue gas desulfurization advantage: high desulfurization efficiency, desulfurization agent can be recycled, the cost is low; In desulfurization and denitration (desulfurization of zhongtong into the proper amount of ammonia to the flue gas at the same time, the ammonia in the copper salt under the catalysis of NOx reduction into N2); Desulfurization can be made into sulfur or sulfuric acid by-product, do not produce solid or liquid secondary pollutants; No need to heat after desulfurization flue gas. This method is the key to use the excellent performance of renewable desulfurizer. The desulfurizing agent should have good desulfurization and regeneration dynamics, good wear resistance, high mechanical strength and low cost, etc.

25kg bags, 500kg bags, 1000kg bags, 200L Galvanized iron (150kg).

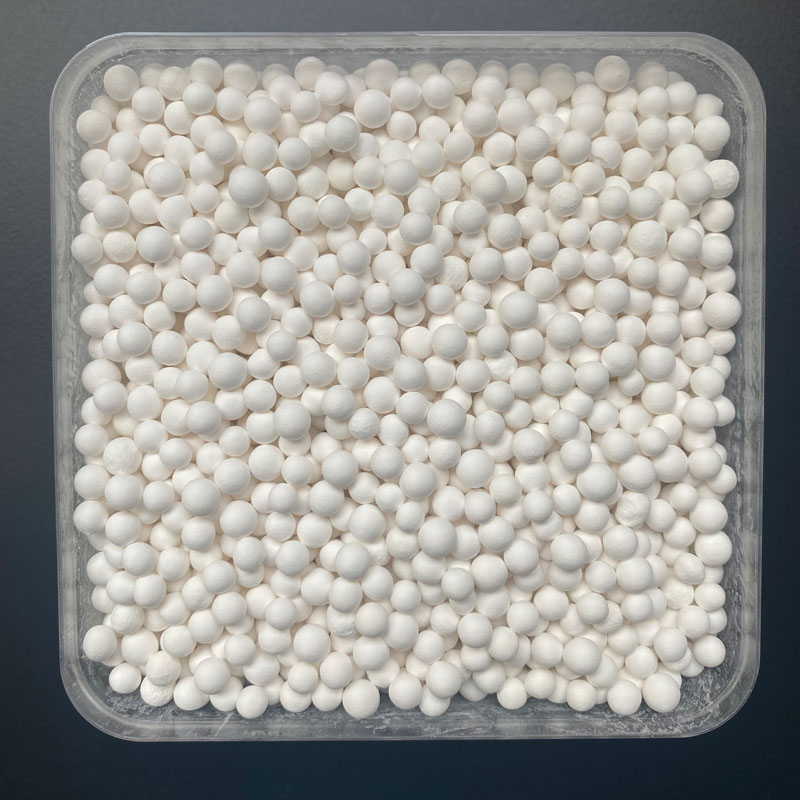

Apperance | Gray sphere | |

Sphere size | Φ2-4 Φ3-5 | mm |

Packed Bulk Density | 0.70-0.80 | g/ cm3 |

Crush strength | 80 120 | N/粒 |

Surface area | 250-300 | ㎡/g |

Total pore volume | 0.45-0.50 | cm³/g |

Abrasion loss | 0.1 | wt% |

AL2O3 | 95 | wt% |

CuO | 5 | wt% |

Zibo Beier Chemical Technology Co., Ltd. has established long-term cooperative relations with many enterprises based on the principle of "customer first and integrity-based". Warmly welcome friends from all walks of life to visit, investigate and negotiate business.

QR Code